A new UK-based Innovation Centre will transform how wheelsets and tracks are approached, developed and maintained in the rail industry.

UK-based Prometheus Connect Ltd, which is also representing Korean rail industry pioneer Asia-Tech Co and world-leading TWI Ltd, has signed a memorandum of understanding which will see the establishment of the international centre.

Two of the most challenging issues faced by rail operators are tightening budgets and increasing lifecycle costs due to the working capital required to enable the day-to-day operation and maintenance of rail services.

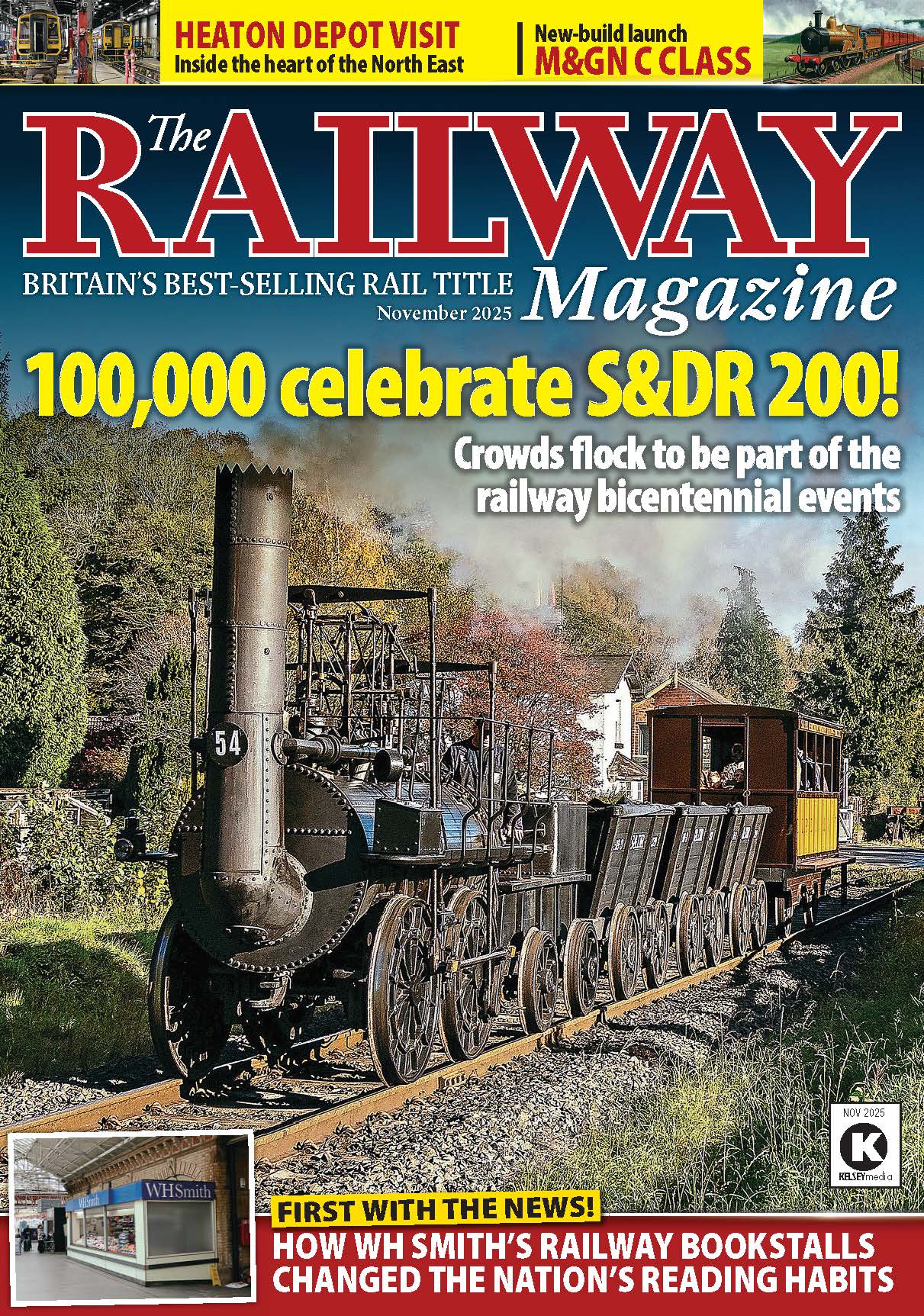

From the history of steam through to 21st century rail transport news, we have titles that cater for all rail enthusiasts. Covering diesels, modelling, steam and modern railways, check out our range of magazines and fantastic subscription offers.

Others include investing in projects such as modernising fleets and infrastructure, achieving decarbonisation toward Net-Zero 2050; the new initiative of the European Climate Foundation, and digital transformation through artificial intelligence (AI) and automation.

With this comes the increasing dissatisfaction levels of railway customers.

In the UK, Network Rail and rail service operators are spending billions of pounds to improve passenger experience.

The rail industry uses a number of key performance indicators including safety, punctuality, connectivity, access, modernisation, and electrification for Carbon Net-Zero.

Nevertheless, the gap between perceived passenger values and the rail industry’s offerings is widening, such that a recent announcement of a 2.7% increase in season ticket prices enraged unsatisfied passengers, as well as consumer groups who are raising their voices against only passengers being burdened with increased costs, which the supply-side doesn’t share.

To tackle these issues, the new Innovation Centre will aim to enable a collaborative approach to determining how to mitigate and reduce lifecycle cost increases in the rail industry.

Collaborative approach

AM for rail wheelsets and tracks, on which: Asia-Tech Co will provide its proprietary technology and expertise; TWI will lead the validation process through testing, inspection and identifying improvements that can take technological developments to the next level; and Prometheus Connect will validate the applicability, deliverability and manufacturability of these developments against achieving a targeted performance that will satisfy industry standards.

The articulation point for this new technology will be when homogeneous AM can be applied to the surfaces of railway wheelsets and tracks, resulting in significantly reduced wheel track rolling, contact fatigue.

Addressing the circular economy for additively manufactured rail wheelsets and tracks, thereby quantifying the economic and social impacts of AM through lifecycle costs, including extending the lifetime of wheelsets and tracks, and making adjustments to new parts procurement recycling and scrap processes.

This will include a carbon footprint assessment using an ‘as-is versus to-be’ model, applied to the AM process in phased deployments including maintenance intervention and redesigning the manufacturing processes of original equipment manufacturers (OEMs). This will serve to illustrate the positive the impact of standardisation in the rail industry, first in the UK and EU, then in Korea and subsequently the rest of the world.

Digital transformation in order to maximise the economic and social impacts of using AM to produce rail wheelsets and tracks, for example, by tracking these assets with analytical models that can generate high quality datasets for machine learning, and thus create a solid foundation on which to build an AI engine for railway asset operation and maintenance. Over time, this will lead to better control of operating costs and an improved customer experience through better performing rail services.

This future-proof approach will play a pivotal role as an innovation engine with which to drive further enhancements in AM of rail wheelsets and tracks, for the benefit of rail industry operators and players.

Creation of a key performance index, as the most significant and influential project for the new Innovation Centre, providing augmented railway industry-specific KPIs that will provide the ways and means with which to inform and measure, industry-wide continuous improvement.

Setting the KPIs appropriately will help and support railway companies and rail safety operators to manage the future performance of their AM rail wheelsets and track while contributing to the circular economy and maximising the benefits of digital transformation.

Tat-Hean Gan, TWI director for Innovation and Skills said “We are excited to be partnering with Prometheus Connect to deliver this dedicated new Innovation Centre for the rail industry.”

“Our objectives are to: develop a masterplan for the establishment of the Innovation Centre, ensuring that it will meet the needs and expectations of rail operators and their passengers; build a creative, innovative team of multidisciplinary experts that can lead a transformative approach to the manufacturing and maintenance of railway wheelsets and tracks; and identify and prioritise the strategic areas for research development and innovation, and AM standardisation” he explained.

Chinui Kim, managing director of Prometheus Connect said: “I am delighted to be partnered with TWI to accelerate the development and adoption of key enabling technologies for realising the Wheels & Tracks-as-a-Service (WTaaS) business.

“WTaaS will support the UK and global rail industries’ efforts to improve the passenger experience by increasing the efficiencies of constrained resources, and leading the digital transformation of comprehensive maintenance with a condition-based and predictive approach, thus ensuring the crucial role of rail transportation in delivering seamless mobility.”

CAPTION FOR IMAGE: Signing of the memorandum of understanding by, from left, Youngjin Lee, Asia-Tech Co, Chinui Kim, Prometheus Connect and Tat-Hean Gan of TWI.